Welcome to our latest blog post where we delve into the intricacies of steel fabrication and its associated costs. As a leader in the industry, Metro Steel understands the critical importance of cost management in steel fabrication to ensure both competitiveness and efficiency in our operations. In this article, we will explore various factors that influence costs in steel fabrication, offering insights that businesses in this sector, including ours, can utilise to optimise their operations. Expect a thorough analysis of everything from material costs to the latest market trends and cost-efficient practices.

Understanding Steel Fabrication

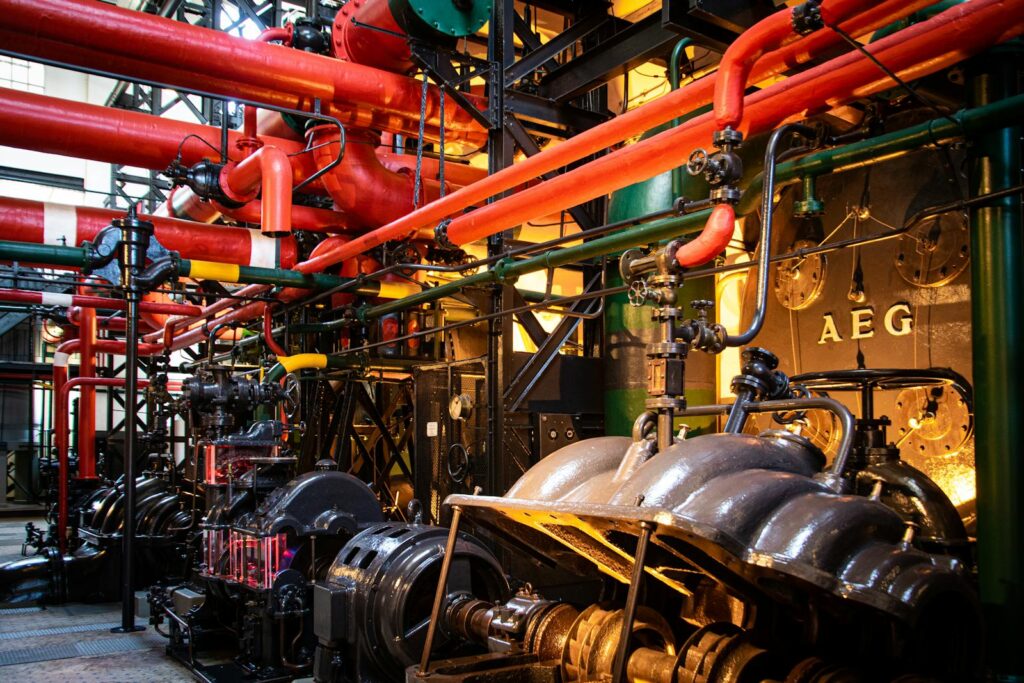

Steel fabrication is a fundamental process in numerous industries including construction, automotive, and shipbuilding. This process involves the cutting, bending, and assembling of steel to create structures and components. The ability to transform a raw material like steel into precise parts and frameworks is crucial for the building of everything from bridges to skyscrapers.

Key Cost Factors in Steel Fabrication

Understanding the key cost factors in steel fabrication is essential for managing budgets and improving efficiency in production. By recognising these factors, businesses can better plan, execute, and streamline their fabrication processes. Below we explore the main components that typically influence the costs associated with steel fabrication.

Materials

The selection and procurement of materials account for a major portion of the total cost in steel fabrication. Different types of steel, such as carbon steel, alloy steel, and stainless steel, each come with unique properties and price points which are influenced by several external factors:

- Market Demand: The demand for steel fluctuates with the economic conditions and the level of activity in key industries like construction and automotive. High demand drives up prices, while lower demand can decrease them.

- Availability of Raw Materials: The availability of iron ore and other alloying elements can impact steel production. Shortages or oversupply can dramatically shift prices.

- Geopolitical Events: Trade policies, tariffs, and international conflicts can affect steel prices globally. For instance, tariffs imposed on steel imports can increase domestic steel prices, impacting the cost of materials for fabricators.

Labour

Labour costs in steel fabrication are significant due to the skilled nature of the work required. The main factors affecting labour costs include:

- Skill Level: The precision and expertise needed to operate advanced machinery and execute complex blueprints demand highly skilled workers, who command higher wages.

- Availability of Skilled Labour: In regions where skilled workers are scarce, labour costs can rise significantly due to the competition for qualified personnel.

- Labour Regulations: Local labour laws and regulations, including minimum wage laws and overtime pay, can also influence overall labour costs.

Technology and Machinery

Technological advancements and machinery are pivotal in steel fabrication, impacting both the quality of output and cost efficiency:

- Capital Investment: Initial investments in high-quality, advanced machinery can be substantial but are crucial for enhancing efficiency and precision in fabrication.

- Maintenance and Upgrades: Ongoing maintenance and periodic upgrades are necessary to keep machinery operating at optimal levels but add to the operational costs.

- Automation: Automating certain fabrication processes can reduce labour costs and minimise errors, but requires upfront investment in robotics and control systems.

Operational Costs

The daily operation of a steel fabrication facility incurs various expenses:

- Energy Consumption: Steel fabrication is energy-intensive, involving welding, cutting, and machining, all of which require significant amounts of electricity and sometimes gas.

- Facility Maintenance: Regular maintenance of the fabrication facility ensures safety and operational efficiency but involves recurring costs.

- Logistics: Costs related to the transportation of raw materials to the facility and the delivery of finished products to clients can vary significantly with fuel prices and logistical complexity.

Compliance and Safety

Compliance with safety and environmental standards is mandatory and involves specific costs:

- Safety Equipment and Training: Investment in safety equipment and training for employees to handle hazardous tasks safely.

- Environmental Compliance: Adhering to environmental regulations can involve additional processes and equipment to reduce emissions and waste.

Market Trends Affecting Steel Prices

Steel prices are subject to a variety of influencing factors tied to global market dynamics:

- International Trade Policies: Decisions by major steel-producing countries to impose or remove tariffs can affect global supply and pricing.

- Supply Chain Disruptions: Events like natural disasters, pandemics, or political instability that disrupt the supply chain can lead to sudden spikes in steel prices.

- Industry Demand Fluctuations: Changes in demand from major consumers of steel, such as the automotive or construction industries, can cause price volatility.

Understanding these factors is crucial for effective cost management and strategic planning in the competitive field of steel fabrication.

Cost-Efficient Practices in Steel Fabrication

In the competitive world of steel fabrication, managing costs effectively while maintaining high-quality output is crucial. Employing cost-efficient practices can significantly influence profitability and sustainability. Here’s how companies are optimising their processes:

Optimising Material Usage

Optimising material usage is paramount in reducing costs in steel fabrication. Techniques such as nesting—arranging patterns to minimise scrap—can dramatically decrease material wastage. Moreover, using software to simulate and plan cuts before actual production helps in maximising the use of materials, ensuring that each sheet or beam is utilised to its fullest potential, thus reducing the need to purchase additional materials.

Leveraging Technology

The use of advanced technology is transforming steel fabrication. Automated cutting machines and CNC systems streamline the fabrication process, ensuring components are produced with high precision and consistency. These technologies not only enhance productivity but also significantly reduce the dependence on manual labour, lowering labour costs and minimising the risk of human error. Additionally, the adoption of robotics for repetitive and high-precision tasks can further boost efficiency and throughput.

Workforce Training

Investing in workforce training is a strategic move that enhances the overall skill level of employees, leading to more efficient operation of complex machinery. Continuous training programs ensure that the workforce stays updated with the latest technological advancements and operational techniques, which can lead to improvements in productivity and reductions in production time and material waste. A well-trained team is also better equipped to troubleshoot and maintain equipment, which can reduce downtime and repair costs.

Metro Steel’s Approach to Cost Efficiency

Metro Steel is committed to driving cost efficiency without sacrificing the quality of our products. We implement advanced manufacturing processes that include high levels of automation to ensure precision and reduce waste. For instance, our investment in state-of-the-art CNC machinery allows for rapid, accurate cuts that optimise material use and reduce excess. Furthermore, our commitment to continuous improvement and innovation enables us to enhance operational efficiencies and keep production costs in check.

Moreover, Metro Steel places a strong emphasis on workforce training, recognising that a skilled team is crucial to maintaining production efficiency and quality. Regular training sessions are held to ensure that our staff are proficient with the latest technologies and methodologies. This not only helps in reducing errors and operational downtime but also boosts employee morale and job satisfaction, contributing to a more productive workplace environment.

Tips for Clients to Manage Steel Fabrication Budgets

Managing budgets in steel fabrication requires a comprehensive understanding of the entire fabrication process along with strategic planning and effective communication. Below are some key strategies that clients can employ to ensure they maximise their budget efficiency without compromising on the quality or timeline of their projects.

Maintain Clear and Consistent Communication

- Detailed Specifications: Provide clear and detailed project specifications from the outset. Detailed drawings and specifications can reduce the need for revisions and avoid miscommunication.

- Regular Updates: Engage in regular communication with the fabricator to stay updated on the project’s progress. This helps in addressing any issues promptly and keeps the project aligned with its timelines.

Effective Project Planning and Timeline Management

- Realistic Deadlines: Set realistic deadlines with the fabricator to ensure high-quality output. Rushing jobs can lead to errors and increased costs.

- Contingency Planning: Build contingencies into project timelines and budgets. Unforeseen issues can arise, and having a plan in place helps in managing them without significant disruptions.

Leverage Technology for Planning and Monitoring

- Use of Project Management Tools: Utilise modern project management tools that offer real-time tracking of project stages and budget status. These tools can help in making informed decisions quickly, adapting to changes, and managing resources more efficiently.

- Digital Mock-ups and Simulations: Before actual fabrication begins, using digital simulations can identify potential issues and inefficiencies, allowing for adjustments without the cost implications of physical prototypes.

By implementing these strategies, clients can play a proactive role in managing their steel fabrication budgets effectively, ensuring that their projects are delivered on time, within budget, and to the required specifications. This collaborative approach not only optimises the use of resources but also builds a stronger relationship with the fabricator, which can lead to better outcomes and potential cost benefits in future projects.

The Future of Cost Management in Steel Fabrication

As we look to the future, the landscape of cost management in steel fabrication is poised for further evolution. Technological advancements, particularly in AI-driven automation and machine learning, are expected to redefine traditional manufacturing processes. These technologies can optimise production planning, predict maintenance needs, and even streamline supply chain management, leading to further cost reductions and enhanced production efficiency.

Moreover, the increasing focus on sustainability in manufacturing practices is likely to influence cost management strategies. The adoption of greener technologies and recycling practices not only supports environmental goals but also helps in reducing waste and energy consumption, which can translate into cost savings. As these trends continue to develop, they will undoubtedly shape the strategic approaches to cost management in the steel fabrication industry.

Conclusion

To conclude, understanding and managing costs in steel fabrication is crucial for the success of businesses like Metro Steel. Through strategic cost management, embracing new technologies, and efficient practices, we continue to uphold our commitment to delivering top-quality products while ensuring cost efficiency. We encourage you to reach out to us to discuss how we can support your fabrication needs with our cost-effective solutions.

Working Hours - Mon – Fri 7:00 AM – 4:00 PM

Working Hours - Mon – Fri 7:00 AM – 4:00 PM Talk to an Expert (07) 3204 1000

Talk to an Expert (07) 3204 1000